Premium Tower Type Detachable Version Hydraulic Breakers

OEM for SANY, XCMG, LiuGong, Zoomlion… | 15% Fuel Saving Certified

We offer hydraulic breakers compatible with excavators, backhoe loaders and skid steers of all brands and models currently available on the market, with excavator weights ranging from 0.5 to 120 tonnes. To select the right hydraulic breaker for your excavators, please provide the brand and model. We are pleased to help you recommend the most suitable hydraulic breakers.

Tips: We offer hydraulic breaker OEM service for all brands and models of excavators, backhoes, and skid steers, catering to bulk purchasing. All products can be engraved with your company name and logo. Of course, you can opt for our private label option.

Complete product specification sheet

Regional Partners and Resellers Inviting

Benefits of Our Resellers and Partners

Welcome to become our regional agent!

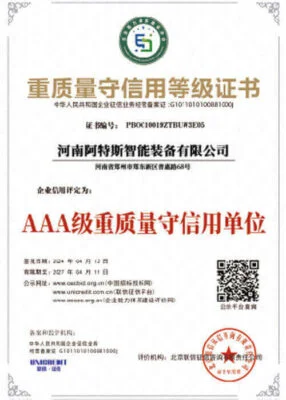

Certificates are worth your trust

Trusted by Global Mining & Construction Industry Leaders

Hear what our OEM partners and distributors say about Artus hydraulic breakers

Other types:

People Also Searched

Hydraulic breaker for excavator, Concrete hydraulic hammers

Fast And Reliable Service For Your Project Or A Quick Support, We Do It All!

Professionally Experienced Sales Butler Team Always Ready To Quick Response To Your Free Consulting.